By Ryan @ ContainerAuction.com

When it comes to prepping, many folks are interested in using shipping containers for a secondary retreat or bug out shelter. However, there are a lot of misconceptions and mislead ideas with regards of how to move them, use them, and maintain them – and we’ve heard most of the questions several times over. The good thing is, with a few exceptions, the questions are all similar. What this tells me is that there’s a consistent path of logic that I can follow, but there’s a little information that the people asking the question haven’t been introduced to. To no fault of their own, it’s really only something that you’d consider if you a) deal with shipping containers on a daily basis, or b) have the same question asked enough times that you do the research yourself. The main areas of missing information are around moving/transporting shipping containers to their site, setting up foundations/burying/covering containers, and retrofitting the unit for proper use.

*For those of you that don’t know what “prepping” is, Prepper Resources describes a prepper as “A thoughtful, determined, self reliant and perceptive person who takes out a tangible insurance policy in order to mitigate the risks which are presented by an often unstable and unpredictable society. This insurance policy involves stockpiling supplies (food, water, medical, personal protection) as well as learning new skills in order to become more self reliant. A prepper’s insurance policy could be compared to auto, medical or life insurance in that when something unpredictable happens (e.g. natural disaster or global food/resource shortages) the prepper is prepared to weather the storm.

A shorter definition from The Daily Prep: Prepping is the practice of acquiring skills and supplies that can be used to mitigate emergency situations….or in plain english, creating fallback plans for when the shit hits the fan!

Moving Shipping Containers: Mislead Idea #1

Idea: I’d like the container moved to my property (location A), then I’ll gradually load it, then I’d like you to come back three months later and move it to my “alternate location” (location B).

Problem: Sure, the shipping container can be moved to location A with no problems. We run into the problem when the trucking company returns to pick the unit up. You’ll need a fork lift or crane on site that can pick it up and put it on the chassis or flatbed, and most people don’t have this type of equipment on site. At this point the project needs to be revised around this obstacle.

Moving Shipping Containers: Mislead Idea #2

Idea: I’m in the planning phase and need two 40′ containers delivered to my vacant lot in the mountains. I’d like them placed in a hole (which may or may not be dug out yet), and I don’t have a fork lift or crane on site.

Problem: A truck driver with a roll off truck doesn’t need a fork lift, but no matter how skilled he is he can’t drop a container of any size in a hole; and for that matter neither can a fork lift. We’re happy to sell you any number of containers, but would also like to see your project be successful. If this is your goal it’s best to have your holes cleared out, contact a local crane operator that’s cost effective enough to be affordable, but large enough to get the job done properly, and have the containers delivered on the same day on a flatbed truck or chassis (which tends to have a cheaper per mile cost than a roll off).

Burying Shipping Containers: Mislead Idea #1

Idea: I’d like to bury my shipping container shelter so that no one can see it.

Problem: On the surface, it’s a great idea and I’d like to do it myself. The sides of shipping containers aren’t designed to hold or support weight for an extended period of time. You’ll need to investigate a way to keep the pressure off the walls of the container. For an idea, read this article on using Gabion baskets to bury a shipping container.

Burying Shipping Containers: Mislead Idea # 2

Idea: I’d like to bury my container shelter completely, and have a few feet of soil on top of the unit.

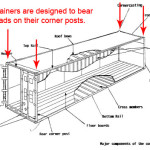

Problem: Just as the walls of a shipping container aren’t designed to hold weight, neither is the roof. Shipping containers are designed to carry their weight in the corner posts, which makes stacking them easier. Think of it like this: Take a piece of plywood and stack two bricks on top of each other under each of the four corners. If you stand in the middle what happens? The result is cracked plywood. The roof of a container will do the same thing given enough time and pressure. If you are fixed on doing this you’ll need to find a way to truss out the top of the unit and keep some of the pressure off the roof, or just not bury it as deep.

Retrofitting a Shipping Container: Mislead Idea #1

Idea: I’m going to buy a container, then stop over at home depot and buy a door and a couple of windows to put in it.

Problem: This can be done, but standard window and door frames aren’t designed for this use, and will require a fair amount of effort to make it work. Containers tend to flex a little, so the frames need to be sensitive to this, as does the seal of the window and the door locks. There are a few suppliers of doors and windows that are specifically designed for shipping containers. Drop us an email and we’ll send you the details (the one we use the most doesn’t have a website yet).

Conclusions

Using containers for a fallback or bug out shelter is a great idea, and done more frequently all the time. As with any project, a strong shipping container shelter takes planning and dedication; and the end product is very rewarding and secure. If you have any questions about buying, moving, or using shipping containers as survival shelters feel free to ask us.

*While most questions are grounded in honest reality, the most concerning one that our staff and industry colleagues couldn’t answer (or wouldn’t – for legal reasons), was “I have a family of four, and a dog. If something happens and my family and I are sealed into a container with supplies, how long can we survive on the air in a 20′ vs. 40′ container?”

ContainerAuction, Inc was founded in 2010 and is working to become a global leader in the sale of new and used shipping containers. We specialize in helping sellers of all sizes market their shipping containers and related equipment. Our management team and advisory board consists of industry professionals with years of experience in container finance, trading, and fleet management.

52 comments

2 pings

Skip to comment form

A very good article, it points out the fallacy of trying to bury a container without some serious planning. We have been able to pickup a 20 ft container with a large loader.

Author

I used to believe that you simply dug a hole and shoved the container inside of it….this is why I’m not a structural engineer. 🙂

“As a rule of thumb, 10 square feet of floor space per person will provide sufficient air to prevent carbon dioxide buildup for up to 5 hours, assuming a normal breathing rate while resting.” ~FEMA CERT manual

Author

Good stuff, thanks for the comment.

Square Ft provides exactly zero air. If you don’t tell us how many CUBIC feet you have told us nothing.

Typical ceiling height is 8′, so it is 8 cubic foot of air per square foot.

I think the common misconception when it comes to anything done “underground” is that there is a “cheap” or cheaper way to do it. Just because it can be done and done cheaper does not mean that it is a good idea to do it on the cheap. In this case, you are talking about putting something underground and this something happens to be designed for above ground use. Other than losing one of my kids, my next biggest fear is suffocating or being buried alive. If these containers are not buried right you will either lose your stuff when it collapses or worse become trapped inside. You will also have to contend with leaking, ventilation issues, etc. and once it is buried it is hard to correct any identified issues.

If you are leaning toward burying a storage container, consult with a professional in your area, preferably someone that has a lot of experience in underground construction.

You’re 100% correct on this. I tried to keep the article as focused as possible, and going into detail could have taken a few chapters (not to mention the liability risk).

The costs can add up quickly, if you’re looking at a cement form for support – cement can get expensive. If you go with Gabion baskets, the rocks that go in them may be free if you source them locally, but you’re talking about some serious man hours to fill them (or as my Dad would call it, “character building”).

A local professional would know best, emphasis on *local* – soil types, compression, water tables, flood zones, they could all come into play.

If it’s done properly it’s great, but this is no place to cut corners or go cheap.

shipping containers seem like a neat idea but burying them could get expensive. Also I would definitely want more than one exit. What about rust and moisture control, would that present a problem. For me I’d want a container only for above ground use and would fortify it with heavy sheet metal for extra protection. If I just had to go underground I’d opt for a cellar with multiple exits and at least one of them hidden from view. Plus with a cellar you can customize the size, shape and interior design that best fits your needs.

Moisture could be an issue, depending on how you form it out. My personal direction would be to notch out the side of a hill and go with the Gabion cages on the hill side between the container and the ground, then put a heavy plastic tarp between the cages and the container (I’m thinking of the blue kind, with the heavy grommets – alternative would be roof tar, but I’ve got little experience with how it ages). Containers are made of COR-TEN steel, with is naturally rust resistent, but any extra precautions are always a good idea.

On the non-hill side I’d run up a little ground, then plant something like a Boston ivy or whatever is natural to the area. Ideally a climbing vine and some trees to break up any lines.

Underneath the container I’d put in a 12-18″ stone bed with some type of french drain to lead the water away from the container.

I also like the idea of two exits – in the hill side idea I’d leave the container doors as one, and possible cut an exit out the top, in the rear of the container – leaving an escape path up/over the hill. But first I’d look into how to make sure it’s water tight and secure.

Excellent Idea

Exactly what we were planning on doing well prior to learning strength of walls now trying to figure out walls on hill side

This sounds like a good idea, well at first anyway. When buying a used container, one should wonder just what has been in there? Has it been used for hauling chemicals? if so, any possible chemical residual problems? One has enough problems (WSHTF) without possible health side effects. If at all possible, purchase a new one. Also two exits is a must, if your found out, well you could be trapped, I have out waited many ground hogs because it didn’t have an alternate entrance or exit. Also will you compromise the structural integrity of the unit by cutting into the walls or ceiling to make a escape door, for long periods of time, you must have fresh air supply as well and a way to exhaust used air, where would be the best place for installing vents? Lot’s of things to think about, my point is, just be safe and make things safe for the family!

Author

Great points John, most containers are treated if I recall correctly. The last thing you want is to be underground in a container with very little fresh air, while chemicals from the treated wood floor slowly poison you and your family.

Depending the type of chemicals they’re moved in different ways. All liquid and some bulk chemicals are transported in tank containers, and the one thing to remember is that everything that goes inside of a container is wrapped and palletized so it doesn’t come into contact with the container itself. Regardless, if you’re able to inspect the container and get an idea of what the inside smells like it’s never a bad idea.

That being said, there are two good options: First, get a used container and change the floor, or to be safe do as John suggests and just buy a new container.

Author

Good stuff Ryan, thanks for clarifying!

I’ve seen several great solutions to this issue. Replacing the floor is definitely an option, but encapsulation is another great (maybe easier) option. There are a few products that will seal in vapors from whatever may have been absorbed by the wood in the floor. There is one epoxy in particular (the name escapes me at the moment but a simple google search will result in at least 1 VERY well written/researched article) that is used to treat the decks of boats, if I remember right, that can successfully encapsulate just about any chemical used to treat cargo in transit.

Also, there is a new type of flooring that is considered “green” that is made out of a plastic or polymer. It’s almost impossible to find in used containers, and is even limited in availability in new containers. We are still having trouble getting details from our Asian counterparts, but it’s out there, and definitely worth looking into if you’re in the market for a container… Especially a new one.

I don’t see my previous comment on here, so I’ll say again… Great article Ryan. I really enjoyed this.

Most nuts shipped are fumigated with phostoxin in the container before leaving port . Request a manifest history for your own peace of mind . One time use containers are not that much more . With the trade imbalance California is accumulating containers . Get together with a group to get a better deal . Inform the seller you are aware of the Panama canal retro fit , and they may make a better deal .

I covered my conex with a used swimming pool liner before covering it up, also used a beam of wood supported by two 8 foot house jacks to support the center. This has been a good root cellar with no problems or leaks going on 5 years now.

How deep do you have it Mike? The pool liner is a good idea, and the house jacks are thin enough not to be a pain to walk around.

I am also curious about this Mike. Would love to see some details if you’re up for it.

How much dirt did you put on top??

Used billboard vinyl would also make a good cover.

A hole in the ground is better known as a “grave.”

Great article!! As someone who does work with containers on a daily basis, these are all questions I am asked all the time. Your answers are perfect!! Containers do make great building blocks, but they do also take some planning! Thanks for writing this!

Author

I can’t take credit for the article but I’m glad you enjoyed it. If you have anything else to add please feel free to do so. 🙂

Burying a shipping container isn’t that large of a challenge. The design capacity of the walls and roof of a shipping container are 300 pounds per square foot. One cubic foot of soil weights 75-100 pounds per cubic foot so 1 foot cover no problem 2 foot cover no problem at 3 foot of cover I would add 4 inch steel beams to the ceiling and walls inside the container every 4 feet which would then allow for up to 7 feet of cover material, do it at 2 feet and well almost 20 feet of cover would be possible. As far as the container rusting not likely to happen they are constructed of cor-ten steel (rust proof) and with a proper coating of some sort of basement coating it should last centuries, provided condensation is controlled on the interior surface which can be done with closed cell spray foam insulation on the interior surfaces. Ventilation isn’t an issue you need it in any type of underground shelter. As far as moving it around on your site get a septic tank installer to do the moving a 500 gallon septic tank weights significantly more than at 20 ft shipping container, these guys are rural and always looking to make a few more bucks. You do need to keep in mind that the structural capabilities of a shipping container are as made start cutting holes in the sides and you will need to add additional support. I think shipping containers are the perfect DIY bunker. First the guy who delivers it will not go OH if SHTF I know were there is a bunker, he thinks just another shipping container for storage on the farm. Keeps the bunker secret for the most part, the main ingredient for a successful bunker!

I have a few 40′ High Cube shipping containers that weigh nearly 10,000 lbs empty. I move them around with my John Deere 710 Backhoe, chain the front and lift it and drag or push around from the corners with the front bucket. Rates for larger loaders and backhoes are probably going be much cheaper than a crane since they are so much more common.

I plan on making a shipping container with my standard 40′ container, PS if you have an option, the HC are so much better having that extra 18″ height. I live 100 miles east of Los Angeles and they are the same price as a standard 40′

I made a carriage for my containers out of mobile home axles and two pieces of large angle iron. Weld the spring shackle supports to the angle iron with the angle iron openings facing inward make the width just right by cutting the axle pipe in the middle then weld it back together then I just lift one end with a large loader ( I use my tractor for 20′ and my High lift dozer for 40’s) then push the carriage under drop the container on and stick a couple bolts through the angle and into the container. Then I can wheel it around wherever I want then just lift it pull the carriage out and set it down. I have done this with several. in fact with my 40′ I took it from the trucking depot to my property behind my truck. (FYI NOT street legal but where I am.. there ain’t much law)

I am glad I came to this site. I was wondering how deep I can install a 20′ container and seen the link to this site. I have learned a lot reading the posts here. I am going to connect 6 40′ containers to make up a home and place 1 large roof over all of them, so it will look like a regular house from the outside. After installing siding on the outside, it will look just like a regular house. I did want to install a 20′ in the ground first and build over just the corner of it.There will be a hatch somewhere in the home that will lead to the “bunker”. I have been thinking about this for about 2 months now and I have the wife on board and she loves the thought of it. I have already worked out was to vent and pipe in air,wires and water. The bunker will be completely self sufficient if ever needed. I am 37 now and wish I started years ago. I will always check the post here just because there is some great information here, THANKS

James, I have looked at that concept and even thought about putting the container in the ground, flush with ground level and then stacking another container on top of it. Anchoring the two together of course, then putting the dirt back so that it just looks like a single shipping container sitting there. Of course, that it one of my “long range” potential projects.

However, doing it that way would alleviate the concern of weight on the top of the container from straight burying it.

I have made cabins out of containers. It is not hard and if you know anything about home construction (wiring, plumbing, etc) anyone can do it. I even have one set as a garage. I used a industrial security roll up door on the side. Welding the structural supports is tricky the first time. The steel takes a hotter setting. You an get the cam locks and even stack thm if you want to. The floors are already sealed with an expoxy. You can use polyurethane for hardwood to reseal if you want. The wood used is apitong and is one of the hardest in the world. Also rot and insect resistant. If you cut a hole for a window or door, just support the opening with a frame of steel angle and weld into place. I used 2×2’s to frame out the walls for wiring and plumbing and then spray foamed and paneled the walls. Wood stove I corner for heat in winter. Google shipping container living for ideas. Popular mechanics even had a full right up it

Author

Paul

What would you ballpark the cost to be to take a standard shipping container from zero to livable? Obviously lots of outside factors in play but just ballpark. $10k? $20k?

No, no, not even close. I did one for probably 4K. (No labor as we did it ourselves) but it’s just 2×2’s drywall and some foam I got on craigs list for insulation. a little conduit and boxes light fixtures etc. It will cost prob 700 more to set up your solar electric system if you do a real nice job on that. Get appliances from old RV’s that is the best for hot water stove and water systems as you want to stay native 12 Volts as much as you can. Vinyl flooring or I used some of the thin hardwood flooring I also got on craigs list but it just depends on what you want to spend. They can be very comfortable and much stronger than a camper or RV

A number of preppers down my way are using new septic tanks and retroing for bug out shelters, smoke houses, “cellars”, etc.

I’M MOVING TO NORTH EASTERN ARKANSAS, AND AM HOPING TO HIDE A CONTAINER UNDER MY 37′ TRAILER…. DOES ANYONE KNOW WHERE I MIGHT GET ONE CLOSE TO THE NO. EASTERN PART OF ARKANSAS… I’M WANTING IT FOR A STORM SHELTER, STORAGE, ROOT CELLAR…..

Memphis will be the closest DEPOT

Hi, I want to make a temporary pool from a 6m long shipping container. Do you know if i would need any extra support? It will only be in use for 3 days.

Any suggestions. Is this structurally safe?

It will be above ground.

I have inherited 5 containers, 20 and 40 foot models, from a neighbor. Is it OK to drag them 1/2 mile down a dirt road with a track loader?….Thanks…Joe

Better to make the carriage I wrote about above

The minute you take the top off of it, it will not be safe. You will have to run channel iron down each side.

An easy way to calculate the total load against the side, without getting into advanced math, is to treat it as strips, with the bottom strip being one foot high,.

1/3 pound x 1 foot x length in feet

the next row is:

2/3 pounds x 1 x length

and so on , then add up the total for all 8 or 9 rows if you have a 9.5 foot high (HC) container. You will be amazed at how high the load is.

Moderator, my reply was meant for Hanel.

Wondering if you were to put a 20′ container in the ground, doors up, and reinforced it to stand up to the pressure or dirt surrounding it, how it would work for a cold storage room? Any thoughts in this?

Hi!

I’m trying to install a window into the side of a moving truck. I know it’s not a container, but I would say they are similar. I got a standard vinyl window second hand that fits perfectly between the aluminum studs of my truck. I would like to build a wood frame as a header, sill plate and cripples. Would this suffice or be possible or is this whole idea no bueno?

Yes, I know this thread is years old, but I thought I’d offer my experience.

I’ve built several underground homes using shipping containers. As the author said, over time the pressure will cause the sides and roof to deform inward. On the sides this was resolved by welding upright supports every 10 feet and horizontal supports, 3 on each side in the center, on 2 foot centers. Where containers were joined side by side, we installed 4″ square steel tubing as supports from the bottom rails to the top rails in order to give added support to the roof. Another option is to leave a few inches of space between the containers and (after making all the cut-outs necessary) pouring concrete into the gap. Concrete has tremendous compressive strength and this can add an enormous amount of support to the overhead load.

The closed cell spray on urethane insulation goes on the OUTSIDE of the container, not on the inside. Putting it on the inside you reduce the space, which is already cramped as it is, and unless the job is properly done there is the possibility of chemical expiration from the foam. On the outside everything under the insulation is converted to thermal mass but water doesn’t condense on the interior surfaces cause the “rain” so common in uninsulated underground structures.

For the top (all of these were buried at least 3 feet down) we welded rebar an inch off the top (in and out of the corrugation) and poured a 4″ slab on top. Because of the corrugation, this was actually half 4-inch and half 5-inch because the corrugations were an inch deep. When (reasonably) cured we sprayed the slab with foam (all the concrete is now thermal mass), covered it all well with plastic sheeting, applied liberal amounts of diazanon (ant killer) and buried it.

All three projects were dug into a hillside to facilitate drainage with a foot of fine sharp gravel and lots of perforated pipe underneath. In one project there was a simple escape hatch in the back of the building with a ladder going straight up through a 3 foot steel culvert onto the top of the home. In the other two the owners opted to build longer “escape tunnels” of varying lengths made from steel culvert. If doing this, make sure they slope down away from the home to prevent any water infiltration into the home. They weren’t that difficult to build, but at $30 a foot the tunnels got expensive quickly.

As to the flooring, I prefer to leave the existing flooring in if it’s in good shape and cover with either hardwood or tile. Probably the best thing about using containers is they can be partially finished before they’re lifted into place. Careful design can result in all the plumbing being in no more than two containers, which makes it much easier to work with.

One very large problem is anyone burying containers will immediately be suspected of running a drug operation. If that’s what anyone has in mind, they’d better have all the equipment necessary to do it all themselves. I won’t even get into the problems with the smart electric meters that know what the power is being used for, but lets just say the cops will be very, very interested in *anyone* putting containers underground.

Kentucky is a really good place to build homes like this because residential farm housing is specifically exempt from the building code. It’s right there in the state law. EXEMPT. The second biggest problem with building an underground home is the code will kill you.

.

.The third biggest problem is the interior has to look better than the average above-ground home in interior appearance and you’d better be able to show the power bills proving how low the utility costs are if you ever want to sell it.

These kind of homes can be built, today, for $30 to $40 per square foot, finished out reasonably well, as long as you’re willing to put a lot of sweat equity into it. That means buying a good stick welder and a good mig welder and learning how to weld, a plasma torch for cutting, various woodworking tools for rough and finish carpentry and a host of other things. For remote locations it’s worth it to buy a used skid-steer and a bucket concrete mixer. It isn’t difficult to find half-yard mixers that run off the hydraulics of the skid-steer. Haul in the gravel, sand and cement and you’re ready to mix and pour. That means learning how to work with concrete.

Before the project is over you’ll have all kinds of tools and new skills.

Author

WOW.!!!!

Awesome real world input. Thank you so much for taking the time to add this.

One thing that was not discussed above I believe is that virtually all containers are mfg in China. Their coatings/paint do not often meet our ‘lead free’ standards, thus you may be putting your long term health at risk with their high lead content paints.

Additionally, if you are buying used containers you will need to check the ease of opening, closing and locking the doors as these are often warped slightly, thus taking a lot of strength to close and lock them. Also you would be wise to install new door seals as the used ones are often hard or damaged. Welding on containers may present some challenge as they are a special steel (CoreTen most frequently) so you may reduce the CoreTen’s ability to resist rust.

FYI: StarBucks Coffee has built several above ground container stores in the Seattle, Denver and Chicago areas.

3 D flooring image is the result of digital printing with the method of application laminate with resin so that the image becomes glossy and looks real http://www.ahlibeton.co.id/p/lantai-3-dimensi.html

I what to thank the author, and all of you who asked questions and provided answers. I have learning a ton of information in just 10 minutes or so. My wife and I have 12 children, so we are going to add a “great room” addition to the back of our house for holidays and Christmas (looking ahead, lots of grand kids). The contractor will frame in and enclose both the new room addition, and frame in the “room” housing the storage container. Once finished with vinyl siding, new roof and gutters; it will look like just one really large room addition from the outside.

My plan is to take a 20 foot container, put it right along side of our great room and have it sitting on 6 reinforced concrete pillars about 3 feet off the ground. A concealed Entrance-way from our existing house to the unit is what I am planning. The container is what i plan on using to store our prepping supplies, and also use it for a “secure-room” for short periods of time, if needed.

So with that being stated, any comments, suggestions, improvements (or even criticisms) are welcome as construction is planned for 6 weeks from now. Thanks

I have a shipping container that I use at my cabin in Michigan and have recently noticed mold on the seams between the floorboards, does anyone else have this problem or know how to get rid of the mold

@sam

Is your container directly on the ground? They need air movement underneath them to stay properly dry.

[…] the editor of Prepper Resources recently posted a good summary guest article that was written by one of the owners of […]

[…] the editor of Prepper Resources recently posted a good summary guest article that was written by one of the owners of […]